1 orchards, mulberry, tea plantations, rubber plantations, forest use in the weeds out of Qi, born in a strong period, per acre with 20% agent 100-200 ml, watered 25 kg, uniform spray weed stems, when when weeds grow to more than 30cm, the dosage should be doubled. nike air max baratas 2 corn, sugar cane, soybeans and other row crop fields wide use before sowing or after sowing pre-treatment process, but also the late crop, the use of protective directional inter-row weed spray Control. cheap nike air max Before sowing or after treatment before sowing seedlings per acre with a 20 percent agent 75-200 ml of water 25 kg spray controlling weeds have been unearthed. cheap nikes Crop growing season, per acre with 20% agent 100-200 ml of water 25 kg, as the line between protective directed spray. asics pas cher 3 practical experience shows that paraquat had no significant effect on the yellow.

Monthly Archives: April 2014

sodium metabisulphite

A detailed description editor

Basic Information

Name

English / Latin names

Sodium Pyrosulfite

Jiaoya Liusuanna

English Name

Supplies: http://www.lubonchem.com

: SODIUM BISULFITE; disodiummetabisulfite; disodiumpyrosulphite; fertisilo; metabisulfitedesodium; Sodiummetabisufite; sodiummetabisulfite (na2-s2o5); sodiumpyrosulfite (na2s2o5); Sodium dissulfite; Sodium disulphite; Sodium pyrosulphite; SODIUM METABISULFITE, PH EUR; SODIUM DISULFITE DRY TECHNICAL; SODIUM METABISULFITE ACS REAGENT ;… SODIUM DISULFITE DRY, RG, REAG ACS, REAG PH EUR;. SODIUM METABISULFITE, 97 +%, ACS REAGE NT; SODIUM METABISULFITE 97 +% ACS REAG &; SODIUM METABISULFITE REAGENT GRADE 97%; SodiumMetabisulphiteA.R;. SodiumMetabisulphiteFcc

Chinese alias

Sodium metabisulfite ; dipropylene sulfite ; weight thioredoxin ; pyrogallol sulfite ; sodium metabisulfite ; metabisulfite ; edible metabisulfite .

CASRN :7681-57-4

EINECS No. :231 -673-0

InchI Code : InChI = 1/2Na.H2O5S2/c;; 1-6 ⑵ 5-7 ⑶ 4 / h;; (H, 1,2) (H, 3,4) / q2 * +1 ;/ p-2

Formula : Na2S2O5

Molecular Weight : 190.09

Appearance: white or light yellow crystalline powder or small crystals ..

Specification: ≥ 65% of sulfur dioxide

Iron ≤ 0.005%

Water insoluble ≤ 0.05%

PH value of 4.0-4.6

Chemical Name

Chinese chemical name : sodium metabisulfite

Chemical Name : sodium metabisulfite

Chinese Name 2 : sodium metabisulfite

Name 2: sodium pyrosulfite / sodium metabisulphite

Technical Manual Code : 1333

CAS No. :7681-57-4

Formula : Na2S2O5

Molecular Weight : 190.09

Ingredients and composition

Hazardous components CAS No.

Sodium metabisulfite 7681-57-4

Category : Antioxidants .

Properties and Applications

Summary

Sodium metabisulfite ; sodium metabisulfite ; heavy thioredoxin ; Sodium metabisulfite; Sodium pyrosulfite formula Na2S2O5 Molecular Weight 190.10 CAS No. 7681-57-4

Physical and chemical properties

The main ingredients: pure

Appearance: colorless prismatic crystals or white powder ; has sulfur smell , sour, salty , ; Storage falling yellow color gradient .

pH:

300(fen jie) “>Melting point (℃):> 300 ( decomposition )

Boiling Point (℃): Not available

Relative density ( water = 1 ) : 1.48

Solubility: soluble in water , acidic aqueous solution ( at 20 ℃ to 54g/100ml water ; 100 ℃ when 81.7g/100ml water ) . Soluble in glycerol, slightly soluble in ethanol. The relative density of 1.4 . Soluble in water soluble in glycerine , slightly soluble in ethanol. Damp decomposition, exposed in air easily oxidized sodium . Contact with acid emit sulfur dioxide and generate the corresponding salts. Heated to 150 ℃ decomposition.

Stability and reactivity

Materials to avoid : strong acids, strong oxidizing agents.

Avoid contact conditions : moist air.

Physical and chemical properties

Sodium metabisulfite is white or yellow crystalline powder or small crystals , with a strong smell of SO2 , the proportion of 1.4 , dissolved in water , acidic aqueous solution , with a strong acid contact with the release SO2 and generates the corresponding salts, long home air, the oxidation into Na2S2O6, so the product can not go far. Higher than 150 ℃, namely decomposition SO2.

Security terms

S26In case of contact with eyes, rinse immediately with plenty of water and seek medical advice.

In case of contact with eyes, rinse immediately with plenty of water and seek medical advice .

S39Wear eye / face protection.

Wear goggles or masks.

S46If swallowed, seek medical advice immediately and show this container or label.

If swallowed , seek medical advice immediately and show this container or label.

Risk Phrases

R22Harmful if swallowed.

Harmful if swallowed .

R31Contact with acids liberates toxic gas.

Contact with acids liberates toxic gas.

R41Risk of serious damage to the eyes.

Serious damage to eyes .

Determination

Thiosulfate

Take this product 1.1g, slowly add dilute hydrochloric acid 10ml, dissolved in a water bath for 10 minutes , let cool, relocated colorimetric tube , add water to 20ml, as was muddy , and sodium thiosulfate solution ( 0.1 control solution mol / L) 0.20ml comparison is made using the same method , no thicker ( 0.2% ) .

Iron

Take this product 1.0g, 5ml of water and hydrochloric acid 2ml dissolved , evaporated on a water bath , the residue with water 15ml 2ml hydrochloric acid , dissolved , add the amount of bromine test solution and the solution of microscopic yellow , heated to remove excess bromine , let cool , add water to 25ml, according to inspection , 2.0ml solution compared with standard control solution made of iron , not deeper ( 0.002% ) .

Heavy Metal

Take this product 1.0g, 10ml water dissolved, add 5ml of hydrochloric acid , evaporated on a water bath , the residue water 15ml, slowly boil for 2 minutes, filtered , and the filtrate was added so that the amount of bromine test solution clarified , heated to remove excess bromine , let cool, add 1 drop of phenolphthalein indicator solution and the amount of ammonia solution until the solution was pink , vinegar salt buffer (pH3.5) 2ml with water to make a 25ml, according to inspection , containing no heavy metals per million dated .

Arsenic

Barium chloride

Name: Barium chloride

Formula: BaCl2

Molecular Weight: 208.23

Risk: Toxic

CAS No.: 10361-37-2

Control Type: Unregulated

Supplies:http://www.lubonchem.com

1 Physical and Chemical Properties

Physical Properties

White crystalline or granular powder. Bitter and salty. Slightly hygroscopic . At 100 ℃ loses crystal water , but placed in the wet air again absorb two molecules of water of crystallization . Soluble in water , soluble in methanol , insoluble in ethanol, ethyl acetate and acetone. The relative density of 3.86 . Melting point 963 ℃, boiling point 1560 ℃, refractive index 1.635 . Barium yellow- green flame reaction

Chemical properties

Barium chloride is commonly used laboratory analytical reagents , mainly for precipitation sulfate , barium sulfate to produce insoluble precipitate .

2 Preparation Method Editor

Reduction on industrial carbon barite get barium sulfide , barium sulfide dissolved in concentrated hydrochloric acid or calcium chloride that was saturated barium chloride . This is the method commonly used , calcium and strontium can be easily removed impurities

3 Use the Edit Profile

Mainly used for metal heat treatment, barium salt manufacturing, electronic instruments , also used for machining heat treatment agent. Determination of sulfate and selenium salts , etc. , chromatography, drip Determination of platinum , water softener . Fabric dyeing .

4 Storage Condition

Store in a cool , ventilated warehouse. Keep away from fire and heat. Packing seal. Should oxidants , acids, food chemicals stored separately and avoid mixing reservoir.

5 hazardous editor

Barium is a virulent , 0.2 ~ 0.5g ingestion can cause poisoning, lethal dose of 0.8 ~ 0.9g. If found poisoned , magnesium or sodium -speed service , taking gastric lavage , enema, vomiting and other measures. Rapid medical treatment, barium poisoning obvious symptoms of hypokalemia . LD50 approximately 118mg/kg.

Sulfamic acid

Name : Sulfamic acid

English Name : ACETO ACID; AMIDOSULFONIC ACID; AMIDOSULFURIC ACID; AMINOSULFONIC ACID; BETZ 0254; SULFAMIDIC ACID; SULFAMINIC ACID; SULPHAMIC ACID; aminosulfuricacid; Imidosulfonic acid; Jumbo; Kyselina amidosulfonova; Kyselina sulfaminova; kyselinaamidosulfonova; kyselinaamidosulfonova (czech); kyselinasulfaminova; kyselinasulfaminova (czech); sulfamic; sulphamidic acid

Grade : AR

CAS No. :5329 -14-6 [ 1 ]

Formula : H3NO3S

Weight: 97.09

supplies: http://www.lubonchem.com

No. MDL: MFCD00011603

EC Number: 226-218-8

2 Products

Raw materials : urea, fuming sulfuric acid, chlorosulfonic acid

Preparation Products : cobalt sulfamate , nickel sulfamate , Acid Green 20 , cyclamate, detergents, alkali superplasticizer , affinity of the toner , ammonium sulfamate , strong detergents , cleaning agents

Characters

Colorless or white crystals , soluble in water, slightly soluble in ethanol and methanol, slightly soluble in acetone, ether insoluble in aqueous solution gradually break down into ammonium bisulfate , water solubility :. 146.8 g / l (20 ℃)

Physical parameters

Melting point : 215-225 ℃

Storage and transportation

Sealed dry place.

Instructions for use

Standard amount of the base titration , complexation masking agents , organic trace analysis of nitrogen and sulfur determination criteria .

Hazard statement

Dangerous code : Xi

Hazard Class : R36/38- R52/53

Security Level : S26-S28-S61

3 Synthetic Method

An amino acid produced in many ways, sulfur dioxide or acetone oxime with hydroxylamine as raw material hydroxylamine , sulfite or sulfate and ammonia as raw materials ammoniting , urea and chlorine acid as raw materials sulfochlorination law , fuming sulfuric acid and urea as raw fuming sulfuric acid , urea , sulfur trioxide and sulfuric acid as raw materials and fuming sulfuric acid method (also known as liquid phase ) and ammonia via gasification and sulfur trioxide in Gas under vapor phase reaction conditions and the like. Domestic and industrial significance of the process has to send two amination with ammonia and direct synthesis of sulfur trioxide fuming sulfuric acid method. Urea is sulfonated with fuming sulfuric acid to form an amino acid in the crude 40-70 ℃, and then water was added for crystallization to obtain the amino acid product. Consumption of raw materials fixed: Urea 2000kg / t, oleum 1500kg / t.

2 , there are two main methods synthesis gas and liquid method. Fumed harsh operating conditions , equipment material requirements . Byproducts and more easily adhere to the amino acids and the reactor wall need regular cleaning. High production costs . The advantage is the high product purity. Manufacturers use mostly liquid phase .

3 excess fuming sulfuric acid in the reaction vessel , cooled with stirring to 20 ~ 40 ℃, start adding the mixed proportion of urea and sulfuric acid . After completion of the addition , stirring at about 20 ℃ 8 h. Then gradually warmed to 70 ~ 90 ℃, distilled sulfur trioxide , cooling crystallization . The crude obtained after the solid-liquid share amino acid, and recrystallized from water , dehydrated and dried to obtain a high-purity quality amino acid.

Four amino acid is a strong Lewis acid and a strong Lewis base NH3 SO3 adduct , prepared a small amount of high purity when the amino acid , in a completely anhydrous conditions , with high purity directly by reaction with ammonia SO3 . If a larger amount of urea is available with fuming sulfuric acid reaction to the system. The round bottom flask equipped with a mechanical stirrer was placed in the water bath , to which was added 560g 100% sulfuric acid under vigorous stirring to 100g of urea times ( about 45min plus End ) was slowly added to sulfuric acid , being careful not the temperature exceed 40 ℃. Then thereto was added 309g of fuming sulfuric acid ( containing 65 % free SO3), and 16h is placed at a temperature of 42 ~ 45 ℃ . Filtered through a glass frit funnel the reaction mixture was washed first with pure sulfuric acid , washed with 50% sulfuric acid , washed with cold methanol and finally with .

5 heating oleum 20% to 30 ℃, urea was slowly added , the temperature controlled at 60 ~ 65 ℃, after adding heat 3H, then warmed to 80 ~ 85 ℃, incubated 2h, after the reaction was cooled to 5 ℃, filtration, drying the obtained crystals by centrifugation , washed with 5% ethanol and recrystallized with distilled water and drained after purification to obtain pure amino acid .

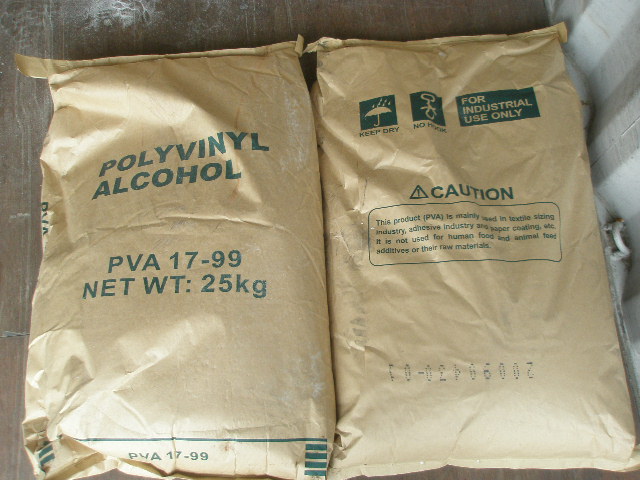

Polyvinyl alcohol

Chemicals Name : polyvinyl alcohol, vinylalcohol polymer, poval, referred to as PVA

CAS No. :9002-89-5

Formula : [C2H4O] n

Molecular weight: 44.05

Structure:Non-toxic

supplies:http://www.lubonchem.com

1,Security terms : S24/25 Avoid contact with skin and eyes Avoid contact with skin and eyes.

S26In case of contact with eyes, rinse immediately with plenty of water and seek medical advice.

In case of contact with eyes, rinse immediately with plenty of water and seek medical advice .

S36/37Wear suitable protective clothing and gloves.

Wear suitable protective clothing and gloves.

S24/25Avoid contact with skin and eyes.

Avoid contact with skin and eyes.

S45In case of accident or if you feel unwell, seek medical advice immediately (show the label whenever possible.)

In case of accident or feel unwell, seek medical advice immediately ( if possible show the label ) .

Risk Phrases R23/24/25Toxic by inhalation, in contact with skin and if swallowed.

Inhalation , in contact with skin and if swallowed poisonous.

2, Technical indicators

Polyvinyl alcohol product standards (cp2010)

No. Index Name Standard

1 Exterior White powder

2 Viscosity 3-70

3 PH value 4.5 ~ 6.5

4 Loss on drying ≤ 5.0

5 Residue on ignition ≤ 0.5

6 Acid value ≤ 3.0%

7 Alcoholysis 85 ~ 89

8 Heavy Metal ≤ 10PPM

Polyvinyl alcohol product standards (USP25)

Low viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 4.0 ~ 7.0

3 PH value 5-8

4 The average molecular weight 16000 to 20000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

Medium viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 21.0 ~ 33.0

3 PH value 5-8

4 The average molecular weight 110000 ~ 130000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

High viscosity

No. Index Name Standard

1 Exterior White powder

2 Viscosity 40.0 to 65.0

3 PH value 5-8

4 The average molecular weight 180000 to 200000

5 Loss on drying ≤ 5.0

6 Residue on ignition ≤ 2.0

7 Water- insoluble impurities ≤ 0.1%

8 The degree of hydrolysis +

9 Organic volatile impurities +

10 Content 85.0% ~ 115.0%

3, Pharmaceutical Grade

Pharmaceutical grade and specifications with EG , EG system uses. Pharmaceutical grade polyvinyl alcohol , polyvinyl alcohol level is different from the chemical industry , it is a very safe organic polymer , non-toxic to humans , no side effects, biocompatible , water-based gel , especially if he ‘s in medical in ophthalmology , wound dressings and artificial joints aspects are widely used in pharmaceutical polyvinyl alcohol film while the film , an artificial kidney film also has to use. Its security can be used to repair skin wounds , eye drops and eye products visible in general. Some models are also often used in cosmetics mask, cleanser , lotion and emulsion , is a commonly used security into film.

4,Risk

Health hazard : inhalation , ingestion or absorption through the skin harmful to eyes and skin

Stimulation.

Explosion hazard: The product is flammable , irritating.

5,Aid measures

Skin contact: Remove contaminated clothing, mobile water rinse .

Eye contact: Did eyelid, mobile water or saline. Doctor.

Inhalation: from the scene to fresh air. If breathing is difficult , give oxygen. Doctor.

Ingestion : drink plenty of water, induce vomiting . Doctor.

6, Fire-fighting measures

Hazardous characteristics : powder can form explosive mixtures with air , when it reaches a certain concentration, when Mars will explode. The thermal decomposition of flammable gases.

Hazardous combustion products : carbon monoxide, carbon dioxide.

Fire fighting methods : firefighters are required to wear gas masks, body wear firefighting suits , fire in the wind . Extinguishing Media: Water spray, foam, dry powder , carbon dioxide , sand.

7 leak handling

Emergency treatment: isolation leak contaminated areas, restricting access. Cut off the fire source . Recommended emergency personnel wearing a dust mask ( full cover ) , wear protective clothing. To avoid dust, carefully scan, bag placed transfer to a safe place . You can also rinse with plenty of water , wash water diluted into the wastewater system . If large spills, using plastic sheeting, canvas cover . Recycling or collection shipped to the waste disposal sites.

8, Handling

Handling Precautions: provide good natural ventilation.

The operator must go through specialized training , strict adherence to rules . Proposed operators wear self-absorption filter respirators , wearing chemical protective safety glasses , wear protective overalls on infiltration , wear rubber gloves. Away from fire , heat, workplace smoking . Use explosion-proof ventilation systems and equipment. Avoid generating dust . Avoid contact with oxidizing agents . Handling of light when light unloading , packaging and containers to prevent damage . Corresponding with the variety and quantity of fire equipment and emergency equipment leakage . Empty containers may be harmful residues .

Storage: Store in a cool , ventilated warehouse. Keep away from fire and heat. Oxidants should be stored separately and avoid mixing reservoir . Corresponding with the variety and quantity of fire equipment . Storage areas should be equipped with suitable material spill .